ISO 9001:2015 Certified

ISO 9001:2015 Certified

Products Finishing Top Shop

Products Finishing Top Shop

ITAR Registered

ITAR Registered

Tin

The Varland Advantage:

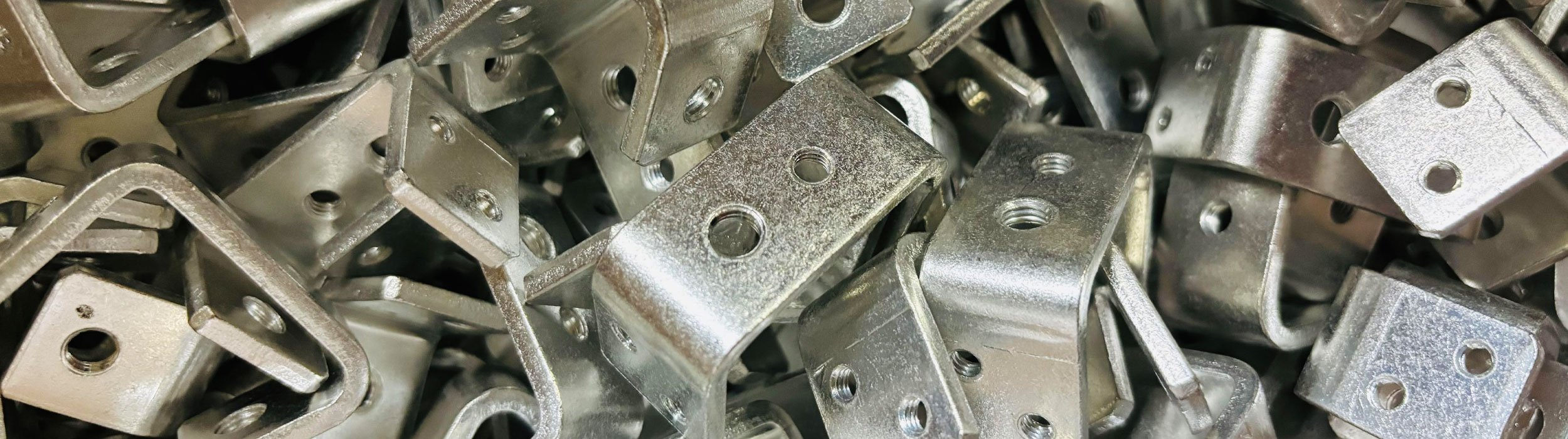

At Varland Plating, we provide both bright and matte acid tin plating solutions tailored to meet the exacting needs of various industries. Whether your project requires a brilliant, reflective finish or a matte surface with excellent solderability, our advanced capabilities ensure precision and consistency with every batch.

Precision Automation: Our automated line offers complete control over barrel speed, amperage, voltage, and plating time, ensuring that your components receive the exact plating thickness required, with the highest level of quality. We maintain comprehensive electronic records for all plating stations, ensuring traceability and performance over time.

Bright & Matte Finishes Available: Choose between bright tin for a highly reflective finish or matte tin for superior solderability, depending on your application needs.

Advanced Thickness Verification: Plating thickness is verified using state-of-the-art x-ray fluorescence to guarantee accuracy and adherence to your specifications.

Industry Approved: Our Tin plating process is Lincoln Electric approved, demonstrating our commitment to meeting industry standards for quality and performance.

Why Choose Tin?

Superior Solderability: Matte tin provides excellent solderability, making it a go-to choice for electrical applications where reliability is critical.

Versatile Applications: Both bright and matte tin finishes are widely used in electrical components, offering flexibility based on the specific needs of your project.

Enhanced Performance with Undercoating: Both finishes can be enhanced with a copper or nickel undercoat to improve performance and durability, particularly in demanding environments.

Excellent Lubricity: Tin is a soft metal, providing exceptional lubricity, which is essential for reducing friction in various applications.

Tailored Tin Plating Solutions

At Varland Plating, we understand that no two projects are alike. That’s why we offer customized tin plating solutions, whether you need a bright, reflective finish or a matte finish optimized for solderability. Our automated and manual lines ensure that your components are plated with precision and consistency, every time.

Committed to Quality

Our state-of-the-art facilities, advanced automation, and rigorous quality control processes ensure that our Tin plating meets the most stringent industry standards. With both bright and matte options, and the ability to apply copper or nickel undercoats, Varland Plating provides versatile solutions tailored to your exact needs.

Download our 2024 Brochure.

Learn more about our 80-year history as a third-generation, family-run business. Discover how our expert team delivers industry-leading quality and service through technology and innovation.

Specifications

Varland plates thousands of different parts for a diverse customer base across a wide range of industries. Some common plating specifications are listed with our processes, but we have experience with many more.

When you choose Varland, we review any applicable specifications to ensure we can meet all the necessary parameters. We won’t put our name on something we don’t understand and that we’re not confident we can complete in accordance with your quality requirements.

-

Electrodeposited Coatings of Tin

-

Military Tin Plating - Electrodeposited For Ferrous and Nonferrous Metals

-

Specification for Electrodeposited Tin Plating